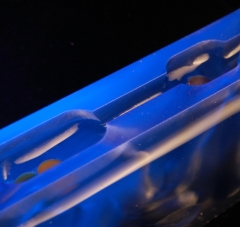

This basic device that utilizes the surface area stress of water to get and control tiny items. Credit: Manoharan Lab/Harvard SEAS A 3D-printed gadget in a tank of water braids nanowires and relocations microparticles. New antennae to gain access to greater and greater frequency varieties will be required for the next generation of phones and cordless gadgets. One method to make antennae that operate at 10s of ghz– the frequencies required for 5G and greater gadgets– is to intertwine filaments about 1 micrometer in size. Today’s commercial fabrication strategies will not work on fibers that little. “It was a shout-out-loud-in-joy minute when– on our very first shot– we crossed 2 fibers utilizing just a piece of plastic, a water tank, and a phase that goes up and down.”– Maya Faaborg Now a group of engineers and researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) has actually established a basic maker that utilizes the surface area stress of water to get and control tiny things. This impressive development provides a possibly effective tool for nanoscopic production. The research study was released in the journal Nature on October26 “Our work uses a possibly economical method to make microstructured and perhaps nanostructured products,” stated Vinothan Manoharan, the Wagner Family Professor of Chemical Engineering and Professor of Physics at SEAS and senior author of the paper. “Unlike other micromanipulation approaches, like laser tweezers, our makers can be made quickly. We utilize a tank of water and a 3D printer, like the ones discovered at numerous town libraries.” The maker is a 3D-printed plastic rectangular shape that has to do with the size of an old Nintendo cartridge. The interior of the gadget is sculpted with channels that converge. Each channel has large and narrow areas, comparable to a river that broadens in some parts and narrows in others. The channel walls are hydrophilic, implying they bring in water. Through a series of simulations and experiments, the researchers found that when they immersed the gadget in water and put a millimeter-sized plastic float in the channel, the surface area stress of the water triggered the wall to fend off the float. If the float remained in a narrow area of the channel, it transferred to a broad area, where it might drift as far from the walls as possible. When in a large area of the channel, the float would be caught in the center, kept in location by the repulsive forces in between the walls and float. As the gadget is raised out of the water, the repulsive forces alter as the shape of the channel modifications. If the float remained in a large channel to begin, it might discover itself in a narrow channel as the water level falls and require to transfer to the left or right to discover a larger area. “The eureka minute came when we discovered we might move the things by altering the cross-section of our trapping channels,” stated Maya Faaborg, a partner at SEAS and co-first author of the paper. “The incredible thing about surface area stress is that it produces forces that are mild sufficient to get small things, even with a device huge enough to suit your hand.”– Ahmed Sherif Next, the scientists connected tiny fibers to the drifts. As the water level altered and the drifts transferred to the left or right within the channels, the fibers twisted around each other. “It was a shout-out-loud-in-joy minute when– on our very first shot– we crossed 2 fibers utilizing just a piece of plastic, a water tank, and a phase that goes up and down,” stated Faaborg. The group then included a 3rd float with a fiber and developed a series of channels to move the drifts in an intertwining pattern. They effectively intertwined micrometer-scale fibers of the artificial product Kevlar. The braid was much like a standard three-strand hair braid, other than that each fiber was 10- times smaller sized than a single human hair. Next, the detectives showed that the drifts themselves might be tiny. They built makers that might trap and relocation colloidal particles 10 micrometers in size– although the devices were a thousand times larger. “We weren’t sure it would work, however our computations revealed that it was possible,” stated Ahmed Sherif, a PhD trainee at SEAS and a co-author of the paper. “So we attempted it, and it worked. The remarkable thing about surface area stress is that it produces forces that are mild sufficient to get small items, even with a device huge enough to suit your hand.” Next, the group intends to develop gadgets that can all at once control lots of fibers, with the objective of making high-frequency conductors. They likewise prepare to develop other makers for micromanufacturing applications, such as developing products for optical gadgets from microspheres. Referral: “3D-printed makers that control tiny items utilizing capillary forces” by Cheng Zeng, Maya Winters Faaborg, Ahmed Sherif, Martin J. Falk, Rozhin Hajian, Ming Xiao, Kara Hartig, Yohai Bar-Sinai, Michael P. Brenner and Vinothan N. Manoharan, 26 October 2022, Nature. DOI: 10.1038/ s41586-022-05234 -7 The research study was co-authored by Cheng Zeng, Ahmed Sherif, Martin J. Falk, Rozhin Hajian, Ming Xiao, Kara Hartig, Yohai Bar-Sinai and Michael Brenner, the Michael F. Cronin Professor of Applied Mathematics and Applied Physics and Professor of Physics at SEAS. It was supported in part by the Defense Advanced Research Projects Agency (DARPA), under grant FA8650-15- C-7543; the National Science Foundation through the Harvard University Materials Research Science and Engineering Center, under grant DMR-2011754 and ECCS-1541959; and the Office of Naval Research under grant N00014-17 -1-3029

Read More

Easy 3D-Printed Device May Pave the Way for Far More Powerful Cell Phones and WIFI