MIT researchers beget demonstrated a 3D-printed plasma sensor for orbiting spacecraft that works correct moreover to great more pricey, semiconductor sensors. These durable, staunch sensors shall be passe successfully on cheap, lightweight satellites identified as CubeSats, that are steadily utilized for environmental monitoring or climate prediction. Credit score: Figure courtesy of the researchers and edited by MIT News

Low-price and immediate to create, these digitally manufactured plasma sensors might maybe per chance abet scientists predict the climate or deem native climate change.

Scientists at MIT beget created the first utterly digitally manufactured plasma sensors for satellites. These plasma sensors, furthermore called retarding capability analyzers (RPAs), are passe by orbiting spacecraft to resolve the chemical composition and ion vitality distribution of the atmosphere.

The 3D-printed and laser-reduce hardware performed moreover to cutting-edge semiconductor plasma sensors. Due to the manufacturing course of, which requires a cleanroom, semiconductor plasma sensors are pricey and require weeks of intricate fabrication. By inequity, these 3D-printed sensors might maybe per chance furthermore be produced for tens of bucks in a matter of days.

Due to their low price and snappy manufacturing, the brand new sensors are ideal for CubeSats. These cheap, low-energy, and light-weight satellites are usually passe for conversation and environmental monitoring in Earth’s greater atmosphere.

The crew of researchers developed RPAs the recount of a tumbler-ceramic area cloth that is more resilient than susceptible sensor materials delight in silicon and skinny-movie coatings. By the recount of the glass-ceramic in a fabrication course of that changed into developed for 3D printing with plastics, they beget been in a position to originate sensors with advanced shapes that can face as much as the broad temperature swings a spacecraft would come across in decrease Earth orbit.

“Additive manufacturing might maybe per chance make an limitless distinction within the manner forward for pickle hardware. Some other folks deem that within the occasion you 3D-print something, you wish to concede less efficiency. Nevertheless we’ve shown that is just not repeatedly the case. Every from time to time there is nothing to alternate off,” says Luis Fernando Velásquez-García, a chief scientist in MIT’s Microsystems Abilities Laboratories (MTL) and senior creator of a paper presenting the plasma sensors.

Becoming a member of Velásquez-García on the paper are lead creator and MTL postdoc Javier Izquierdo-Reyes; graduate pupil Zoey Bigelow; and postdoc Nicholas K. Lubinsky. The analysis is published in Additive Manufacturing.

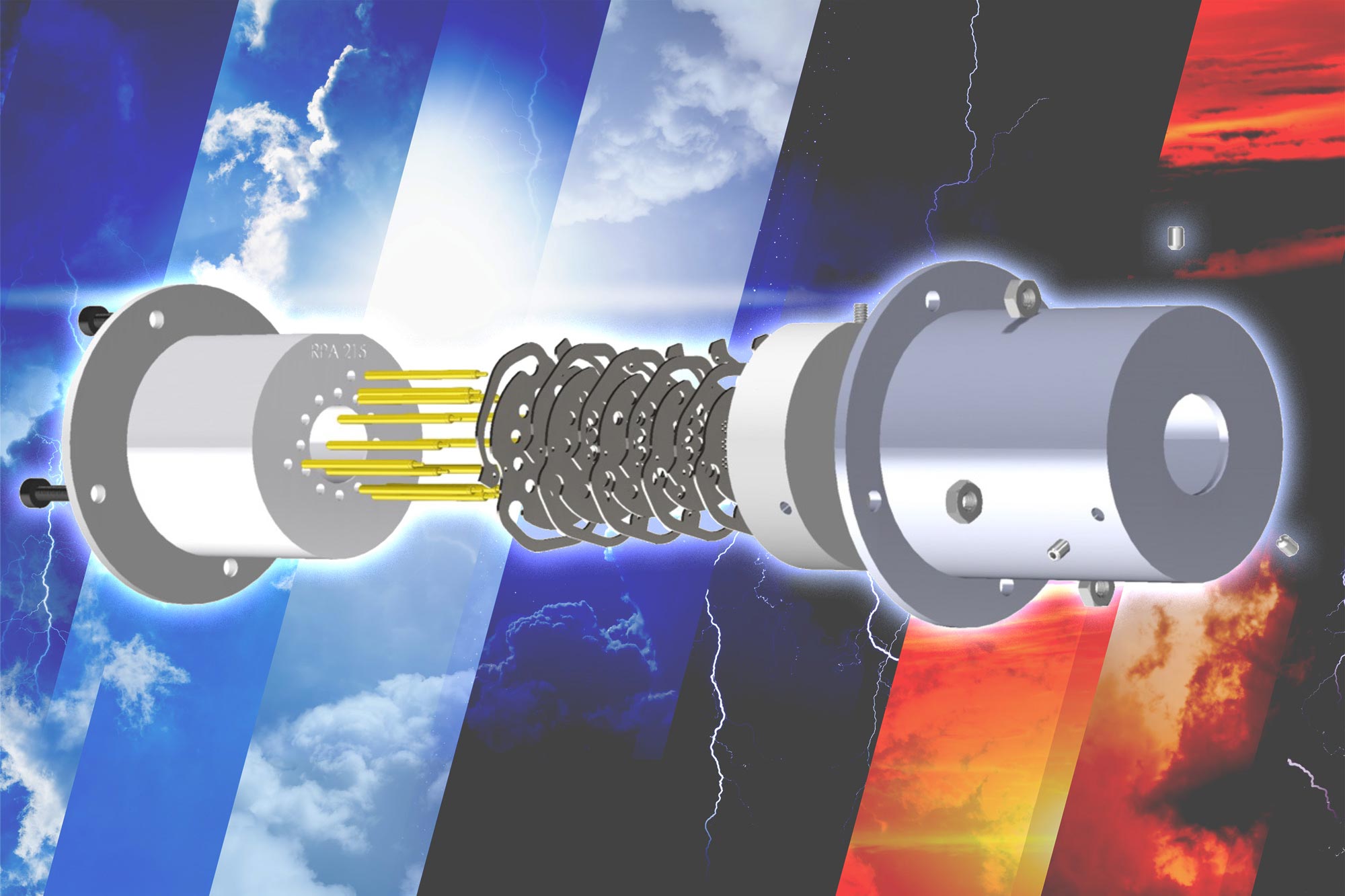

In an RPA, plasma passes by technique of a group of electrically charged meshes dotted with slight holes. As the plasma passes by technique of every mesh, electrons and other particles are stripped away until most bewitching ions remain. This resolve reveals how the meshes match interior the RPA housing, which aligns the meshes. Credit score: Courtesy of the researchers

Versatile sensorsAn RPA changed into first passe in a pickle mission all of the manner attend in 1959. The sensors detect the vitality in ions, or charged particles, which shall be floating in plasma, which is a superheated combine of molecules repeat within the Earth’s greater atmosphere. Aboard an orbiting spacecraft delight in a CubeSat, the versatile instruments measure vitality and conduct chemical analyses that can abet scientists predict the climate or song native climate change.

The sensors own a group of electrically charged meshes dotted with slight holes. As plasma passes by technique of the holes, electrons and other particles are stripped away until most bewitching ions remain. These ions make an electrical contemporary that the sensor measures and analyzes.

Key to the success of an RPA is the housing construction that aligns the meshes. It desires to be electrically insulating whereas furthermore in a position to face as much as surprising, drastic swings in temperature. The researchers passe a printable, glass-ceramic area cloth identified as Vitrolite that shows these properties.

Pioneered within the early 20th century, Vitrolite changed into typically passe in radiant tiles that develop into a total seek in art deco constructions.

The durable area cloth can furthermore face as much as temperatures as excessive as 800 degrees Celsius (1472 degrees Fahrenheit) with out breaking down, whereas polymers passe in semiconductor RPAs launch to soften at 400 degrees Celsius (752 degrees Fahrenheit).

“In the occasion you are making this sensor within the cleanroom, you don’t beget the identical level of freedom to interpret materials and constructions and how they work collectively collectively. What made this capability is the latest trends in additive manufacturing,” Velásquez-García says.

This resolve reveals an experiment in which the researchers pickle up their RPA to indicate it as an ion vitality distribution sensor. Credit score: Courtesy of the researchers

Rethinking fabricationThe 3D printing course of for ceramics typically involves ceramic powder that is hit with a laser to fuse it into shapes. On the other hand, this course of typically leaves the area cloth shameful and creates susceptible parts attributable to the excessive heat from the lasers.

As an alternative, the MIT scientists passe vat polymerization, a course of equipped decades ago for additive manufacturing with polymers or resins. With vat polymerization, a 3D construction is constructed one layer at a time by submerging it typically right into a vat of liquid area cloth, in this case, Vitrolite. Ultraviolet light is passe to medication the area cloth after every layer is added, after which the platform is submerged within the vat over again. Each layer is most bewitching 100 microns thick (roughly the diameter of a human hair), enabling the creation of subtle, pore-free, advanced ceramic shapes.

In digital manufacturing, objects described in a fashion file might maybe per chance furthermore be very intricate. This precision allowed the researchers to make laser-reduce meshes with weird and wonderful shapes so the holes lined up perfectly when they beget been pickle interior the RPA housing. This allows more ions to go by technique of, which ends in greater-decision measurements.

Because the sensors beget been low-price to create and shall be fabricated so snappy, the crew prototyped four weird and wonderful designs.

While one fashion changed into in particular efficient at capturing and measuring an limitless different of plasmas, delight in these a satellite tv for computer would come across in orbit, one other changed into neatly-suited to sensing extraordinarily dense and chilly plasmas, that are steadily most bewitching measurable the recount of ultraprecise semiconductor units.

This excessive precision might maybe per chance allow 3D-printed sensors for capabilities in fusion vitality analysis or supersonic flight. The snappy prototyping course of might maybe per chance even spur more innovation in satellite tv for computer and spacecraft fashion, Velásquez-García provides.

“In the occasion that that it’s probably you’ll wish to innovate, you wish to beget the power to fail and afford the possibility. Additive manufacturing is a truly assorted technique to make pickle hardware. I might maybe per chance make pickle hardware and if it fails, it doesn’t matter because I might maybe per chance make a new edition in a brief time and inexpensively, and in actuality iterate on the form. It is miles sandbox for researchers,” he says.

While Velásquez-García is chuffed with these sensors, he desires to enhance the fabrication course of within the halt. Reducing the thickness of layers or pixel dimension in glass-ceramic vat polymerization might maybe per chance make advanced hardware that is great more staunch. Furthermore, fully additively manufacturing the sensors would make them delight in minded with in-pickle manufacturing. He furthermore desires to explore the utilization of synthetic intelligence to optimize sensor fashion for explicit recount instances, equivalent to deal cutting again their mass whereas ensuring they continue to be structurally sound.

Reference: “Compact Retarding Skill Analyzers Enabled by Glass-Ceramic Vat Polymerization for CubeSat and Laboratory Plasma Diagnostics” by Javier Izquierdo-Reyes, Zoey Bigelow, Nicholas K. Lubinsky and Luis Fernando Velásquez-García, 13 July 2022, Additive Manufacturing.

DOI: 10.1016/j.addma.2022.103034

This work changed into funded, in allotment, by MIT, the MIT-Tecnológico de Monterrey Nanotechnology Program, the MIT Portugal Program, and the Portuguese Foundation for Science and Abilities.